| 제목 | [DAIKIN] GOVERNMENT - AJ Celebrezze Federal Building | 작성일 | 16-06-16 14:50 |

| 글쓴이 | 최고관리자 | 조회수 | 3,445 |

본문

CASE STUDY

Government

Name

A. J. Celebrezze Federal Building

Location

Cleveland, OH USA

Facility Size

1.5 million ft2 multi-use facility

Issue

37 year old fan coil equipment not providing reliable heating or cooling

Solution

Update fan coil units with the latest technology to reduce energy costs

and improve occupant comfort

Cleveland skyscraper enters new era of energy efficiency, tenant comfort, $4.5 million under budget, two months ahead of schedule

Designed by architect I. M. Pei in the 1960s as part of Cleveland's urban renewal project, the Anthony J. Celebrezze Federal building retains the broad-shouldered, confident visage typical of the glass-and-steel office buildings of the era. After 35 years, though, the inside of the 32-story building was beginning to show its age.

The HVAC system was not only inefficient, but uncomfortable. Tenants complained that the fan coil units, located in offices around the perimeter of the building, were disruptive and provided ineffectual heating and cooling.

Following a building-wide assessment, engineers at Westlake Reed and Leskosky, Cleveland, designed a mechanical upgrade to reduce energy costs and improve tenant comfort. This included replacing the existing 4,640 fan coil units with new, custom-designed models from Daikin.

The project became a study in organization and efficiency—so efficient, in fact, that it was completed two months ahead of schedule and $4.5 million under budget.

A major requirement of the renovation dictated the course of the project: the building was to remain fully occupied and functional during the upgrade. To accomplish this, contractor teams went to work after the building's employees went home for the day—replacing fan coil units four nights a week, every week, for almost a year. When employees arrived at their offices the next morning, the only evidence of the overnight overhaul were the new fan coil units—custom designed by Daikin to minimize installation time.

Assembly-line efficiency was a key to the project's success, according to Jeff Klie, the mechanical contractor who managed the project for the Smith & Oby Company. "You've heard of the perfect storm? The Celebrezze project could have been one, but it became the perfect project instead." Also important was close project coordination between the General Services Administration (GSA), Smith & Oby, and Daikin. "When you are able to get done two months ahead of schedule and $4.5 million under budget," noted Klie, "it speaks to the team effort."

Renewing an "urban renewal" building

About 5,500 federal employees work in the structure, including staffs of the Defense Finance and Accounting Service, Internal Revenue Service, Small Business Administration, Equal Opportunity Employment Commission, the Coast Guard, and the departments of Veterans Affairs and Housing and Urban Development.

On each floor, four-pipe fan coil units supply zoned heating and cooling to offices on the perimeter of the building. The four-pipe system (hot and cold water supply and return) allows some units to be in heating mode and others in cooling at the same time. It also allows for reheating of cold dehumidified air before it enters the work place. Depending on room size, each office has 4, 6 or 8 fan coil units. Air handling units located in the basement circulate conditioned air to central spaces throughout the building. Chilled water for the system comes from an off-site, central chilling system operated by Cleveland Thermal Energy.

A major component of the building renovation was replacing the original 37-year-old fan coil units, which had outlived their usefulness in terms of comfort, efficiency and maintenance. The only temperature control for the units was changing fan speeds (low, medium or high) so employees were often either uncomfortably cold or hot. Drain pans on some units collected moisture, so indoor air quality was a concern. In addition, the need for constant maintenance and repair was disruptive for tenants and a financial burden for building management.

To alleviate these problems, Daikin designed the new fan coil units to accommodate a wide range of temperature preferences. Modulating valve control is included to provide more even heat distribution and less fluctuation in temperatures by controlling both the temperature of the air delivered and the fan speed. A high-efficiency centrifugal fan assembly helps minimize noise and vibration for increased occupant comfort.

Multi-directional grilles let users direct the airflow from the units toward the windows in the winter, to minimize drafts, and toward the room in the summer, for increased cooling comfort. Filters are easily replaced via a hinged door on the front of the units. Drain pans and coils are readily accessible for cleaning via a quick-snap panel.

Each fan coil unit is factory-fitted with LonMark® direct digital controls for efficient unit operation. Valve control and temperature set point adjustments are accessible through a hand-held device. Quick connects on sensors and relays simplify servicing and replacement. Communication wiring is run from controller to controller using a standard plug-in jack and Ethernet cable, making a continuous loop around the perimeter of the building. Technicians simply plug in the units to the pre-wired system during installation. A future project will tie these units into a building automation system.

Because on-site installation was limited to after-hours, Daikin designed the fan coil units to be virtually "plug and play." New units fit the exact footprint of those being replaced, even though the originals were not manufactured by Daikin. Primary time-saving features included factory-installed and insulated horizontal piping (supply, return and condensate piping; five total per fan coil unit) and a unique joining technology for connecting the units on-site without soldering. Specially designed, wheeled carts were also provided for maneuvering the units down halls and rolling them into place for installation.

Executing the plan

While Daikin designed all 4,640 units for quick and easy installation, the contractor developed methods and materials for the assembly-line project that would make the operation nearly invisible to the building's occupants. The 23-man crew, including pipe fitters, electricians and laborers, worked 10-hour days, beginning at 6 p.m. after the building was empty. "Coordination, organization, and cooperation – all of those things were very important," Klie said.

During installation, pipe-fitting technicians hung the fan coils on existing steel racks with custom-made angle-iron clips. Piping was connected from one unit to the next using a solderless coupling technology which eliminated the need to haul propane tanks on the job and reduced the risk of fire. It also allowed the teams to meet their quota of installing 30 fan coils per night. "All my guys had to do was slip the coupling section on and slide it to the unit," Klie said. "They secured each connection with a crimp and placed insulation over the coupling. That saved us a lot of time and made us very efficient."

Once the units were installed and connected, crews started a two-hour pressure test for leaks, took a dinner break, and then installed the fan coil covers when they returned. "It was very much like a wheel – turning, turning, turning," Klie said. "It was very repetitious, but also very efficient."

As the new fan coils were installed, laborers carted away the old units, disassembled them and separated the steel, brass and copper into bins. The resulting 664,000 pounds of metal was recycled, Klie said, for which General Services Administration received a federal recycling award.

The work each night didn't end until the space looked exactly as it did before the work began. Crews dismantled partitions, moved desks and other furniture, and even took digital photos to ensure pictures and other mementos on the wall were put back in the same place. "In the morning, it was just like we were never there," Klie said.

The finished project has drawn accolades from the building's tenants, including military officials who thrive on precision and efficiency. According to Klie, "Coast Guard officials told us, 'What you did was military-esque.'"

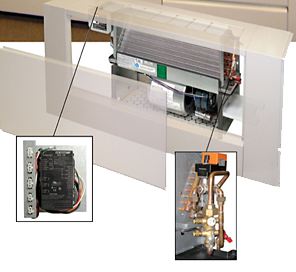

The project to replace 4,640 fan coil units at the Anthony J. Celebrezze Federal Building was completed under budget and ahead of schedule. New Daikin units located under windows at the perimeter of the building, feature factory-installed DDC controls (left inset) and modulating valves (right inset) for even cooling and heating distribution with minimal temperature fluctuation.

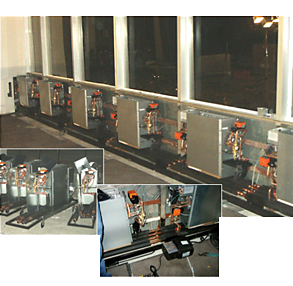

New fan coil units were delivered to the building each night, on specially designed, wheeled carts (right, top inset) ready for installation. Factory-installed horizontal piping (right, bottom inset) was connected from one unit to the next using a solderless coupling technology. Once units were installed (right) crews started a two-hour pressure test for leaks, took a dinner break, then installed the fan coil housings (below) when they returned.

Custom-designed housings on the fan coils give each office an updated look and frame the skyscraper view of downtown Cleveland and Lake Erie.

| 이전글 | [DAIKIN] ENTERTAINMENT - Philharmonic Center for the Arts 2016-06-16 | ||

| 다음글 | [DAIKIN] GOVERNMENT - Arizona Arid-Land Research Center 2016-06-16 | ||