| 제목 | [DAIKIN] GOVERNMENT - Robert E. David Building | 작성일 | 16-06-16 14:26 |

| 글쓴이 | 최고관리자 | 조회수 | 4,595 |

본문

CASE STUDY

Government Office Building

Name

Robert E. David Building

Location

Columbia, SC, USA

Facility Size

106,380 est. ft2

Issue

Procure a quiet chiller with the best life-cycle cost over a 20-year period of operation

Solution

(1) 260-ton Daikin Magnitude® magnetic bearing centrifugal chiller

Daikin delivers 37 percent annual energy savings to South Carolina state agency

Issue

The Robert E. David building, a six-story state office building in Columbia, South Carolina, was due for an energy-saving upgrade. The South Carolina Department of Employment and Workforce sought to make improvements to the 1975-built David building, which houses its administrative headquarters.

Energy managers at the South Carolina agency saw an opportunity to reduce the building’s energy usage with a renovation that included upgrades to allow for more energy-efficient lighting, HVAC, and building controls. The HVAC upgrade required replacing the building’s 40-year-old two-pipe, centrifugal water-cooled chiller system. The upgrade also required a flexible workhorse given the region’s humid, subtropical climate, which calls for air conditioning much of the year and flexibility to deliver heat during the chill of winter months.

Mechanical Design, Inc. (MDI), the mechanical engineering firm on the project, provided engineering services for the replacement of the chiller, chilled-water pumps, condenser-water pumps, and all related piping. “Most state office buildings have hot-water heat and this building relies on electric strip heaters for warm air. One key objective of the separate controls upgrade was to avoid the use of simultaneous heating and cooling,” says Danny Wilds, P.E., LEEP AP, president of MDI in Columbia, SC.

“The customer was looking for high energy-efficiency and low sound in a replacement chiller as noise was a consideration since the mechanical room is located above executive offices,” says Todd Woodrow, Daikin Applied representative and sales engineer at Hoffman & Hoffman, Inc. in Cayce, SC.

Solution

The process to vet chiller manufacturers and specific products began in 2012. “The customer was looking for the chiller with the best lifecycle cost over a 20-year period of operation,” Wilds says, adding the specification process also required the new chiller to meet a noise threshold of 81.5 dBA.

Among a number of manufacturers considered, hands down, Daikin beat out the competition with its Magnitude magnetic-bearing chiller, on a lifecycle-cost basis. The award-winning Magnitude chiller renders part-load performance of .32 kW/ton IPLV and sound pressure ratings as low as 76 dBA. “The Magnitude chiller hardly ever has to run at full capacity and the part-load efficiency (of .32 IPV) was taken into account for our firm to calculate cost on weighted averages of operation throughout the year,” Wilds says.

“From the chiller standpoint, using a magnetic-bearing chiller is unique. The renovation also brought the ability to better control the electric heat which also contributes to significant energy savings for the owner,” Wilds says. The controllers in the variable air volume (VAV) boxes that modulate cool air were also replaced as part of a separate contract.

Reduced kilowatt usage of the high-efficiency Magnitude chiller contributes to the owner’s energy savings.

Mechanical contractors McCarter Mechanical of Spartanburg, SC, removed the old chiller and installed the Daikin chiller in early 2013. Adds Woodrow of Hoffman & Hoffman: “The new chiller was started up in March 2013 and the project overall was a quick change-out with the work done over a 4-6 week period.”

The unusually warm winter temperatures that occurred during the replacement process was one of the only challenges the project team encountered. With the air conditioning inoperable and dynamic weather hard to predict, it was a temporary inconvenience. Yet, the agency didn’t believe it needed to address a temporary cooling solution since the equipment changeout would occur quickly.

During the chiller project in 2012-2013, a new building automation system featuring direct digital controls (DDC) was installed to replace the building’s original pneumatic controls. “In addition to new controls and the chiller technology, having non-simultaneous heating and cooling helps to control the owner’s energy costs,” Wilds says.

Outcome

“Replacing our 40-year-old chiller with the new Daikin magnetic-bearing frictionless chiller, along with new DDC controls, has really been a great energy savings for our agency,” says Doug Kirkland, facilities manager at the South Carolina Department of Employment and Workforce (DEW) in Columbia, SC.

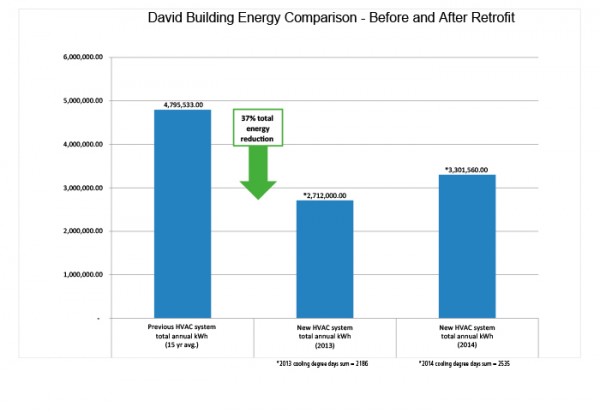

The Daikin Magnitude chiller contributes to impressive energy savings at the DEW. Since the new chiller system, controls, and lighting were installed, on a two-year average of 2013 and 2014, the state agency has realized energy savings of approximately 37 percent annually. Moreover, the agency also received an incentive rebate on its capital investment in the Daikin Magnitude chiller from the South Carolina Electric & Gas Company’s EnergyWise program of $29,640.

DEW appreciates the preventative maintenance from the Daikin Service Group. “The chiller has been performing flawlessly with no real issues to speak of. We have it on a yearly maintenance program that keeps it running at peak performance and provides us with confidence that the system will remain operational for our employees and customers,” Kirkland concludes.

| 이전글 | [DAIKIN] GOVERNMENT - Dallas NWSC 2016-06-16 | ||

| 다음글 | [DAIKIN] GOVERNMENT - Federal Hall National Memorial 2016-06-16 | ||